“UNISTELLAR has created a nearly foolproof instrument that even novice skywatchers will have a blast with.”

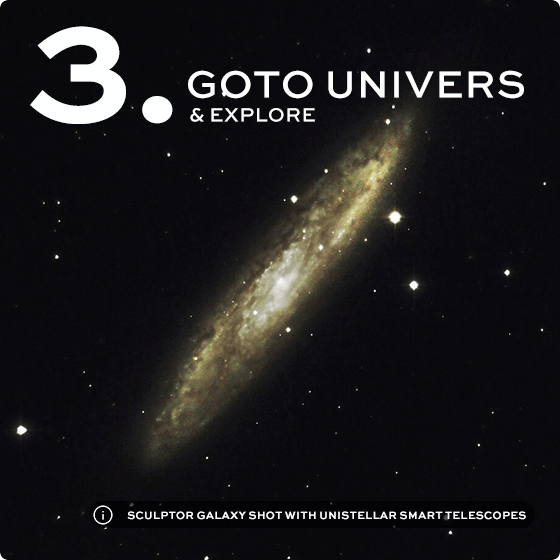

Discover the Universe Through Our Community’s Eyes

Explore stunning images captured by Unistellar users from around the world. From galaxies and nebulae to planetary close-ups, this gallery showcases the passion, creativity, and discoveries of our vibrant astronomy community.

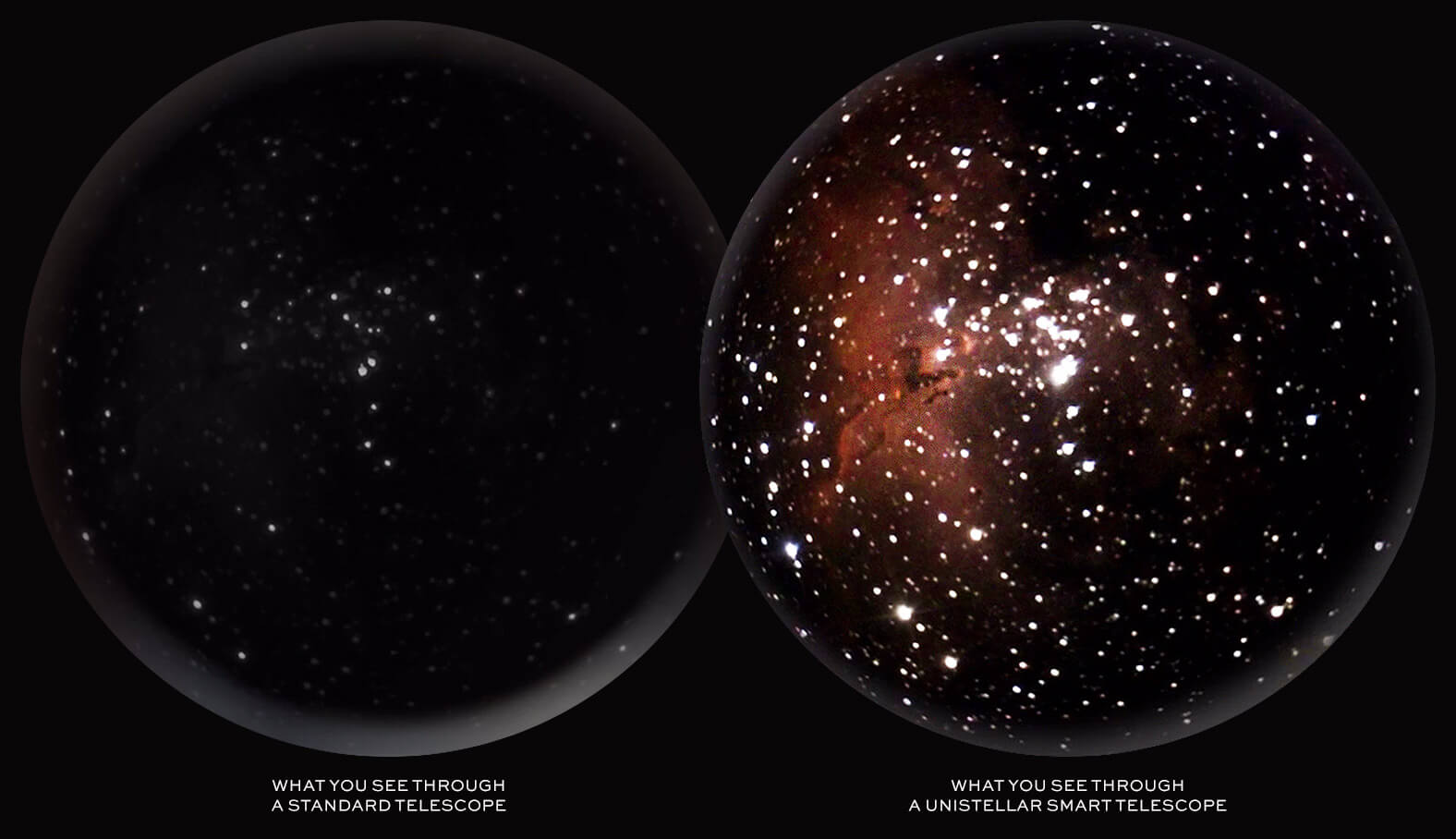

AN UNRIVALLED EXPERIENCE

A true revolution in astronomical observation, UNISTELLAR’s exclusive Dynamic Signal Amplification Technology increases the light signal in real time. The levels of intensity, detail and coloration obtained are unprecedented in the world of consumer telescopes.

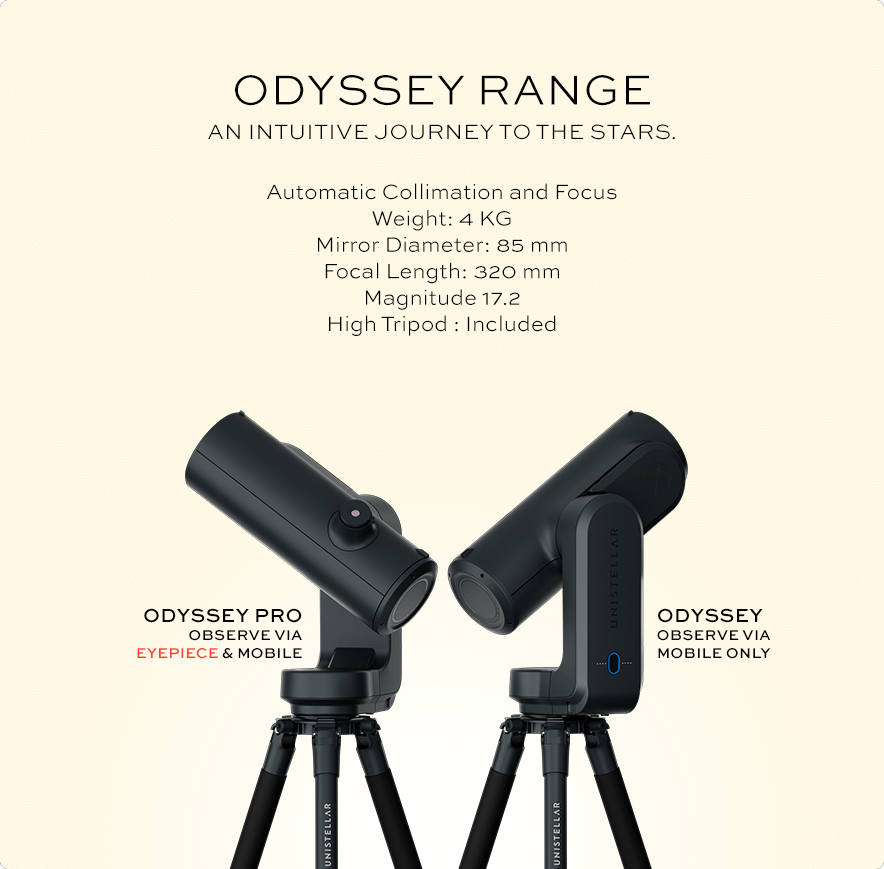

THE COSMOS IN 2 MINUTES

There’s no need to make tedious adjustments, use bulky equipment or plan your observation nights in advance: UNISTELLAR smart telescopes tell you which object to observe according to your position, point at it and follow it automatically.

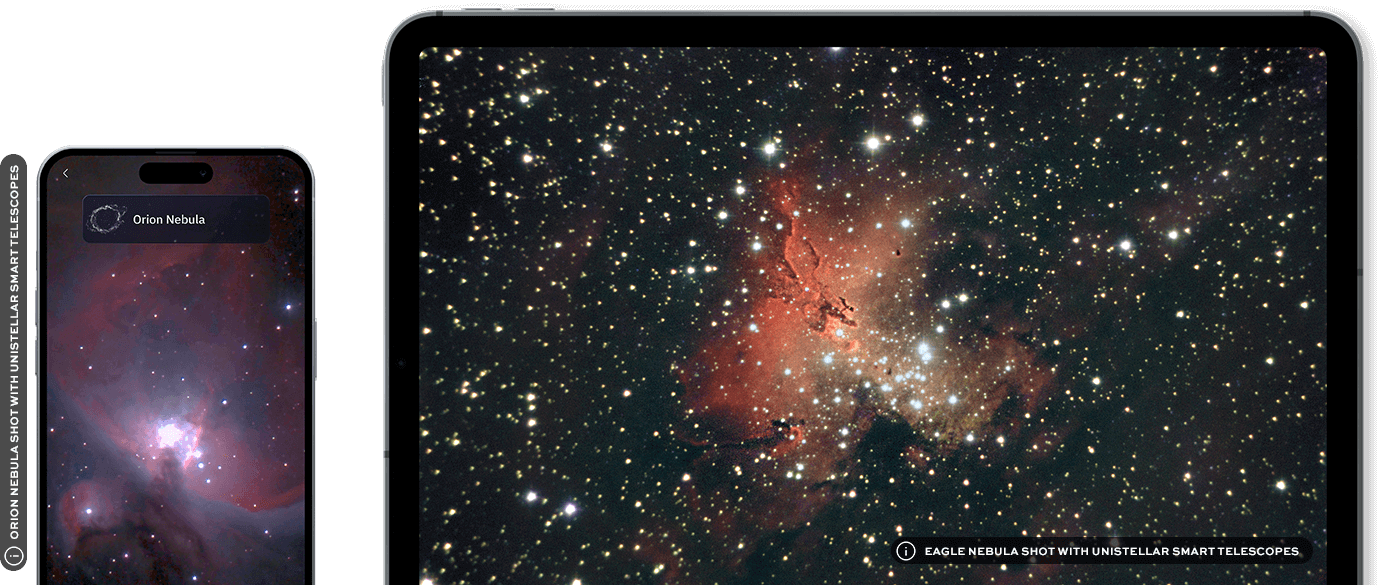

A JOURNEY TO SHARE

Control your smart telescope from your smartphone or tablet with the UNISTELLAR App. Navigate the cosmos, capture your astronomical discoveries with a simple click, and share unforgettable memories with family and friends.

ENVISION

Precision optics and smart AR overlays guide & elevate your night sky and daylight vision Unleash your inner trailblazer.

CITIZEN SCIENCE

contribute to space missions

Join our Citizen Science programs and become part of a global community making real astronomical discoveries and contributing to groundbreaking scientific research.

Blog

What’s new

Explore our blog for exciting space exploration updates and inspiring community stories.

Use Cases

A Universe of

Possibilities

Shape your stargazing journey to fit your unique astronomical aspirations.

Support

Got Questions? We’re Here to Help

Our dedicated support team is trained to provide expert guidance.